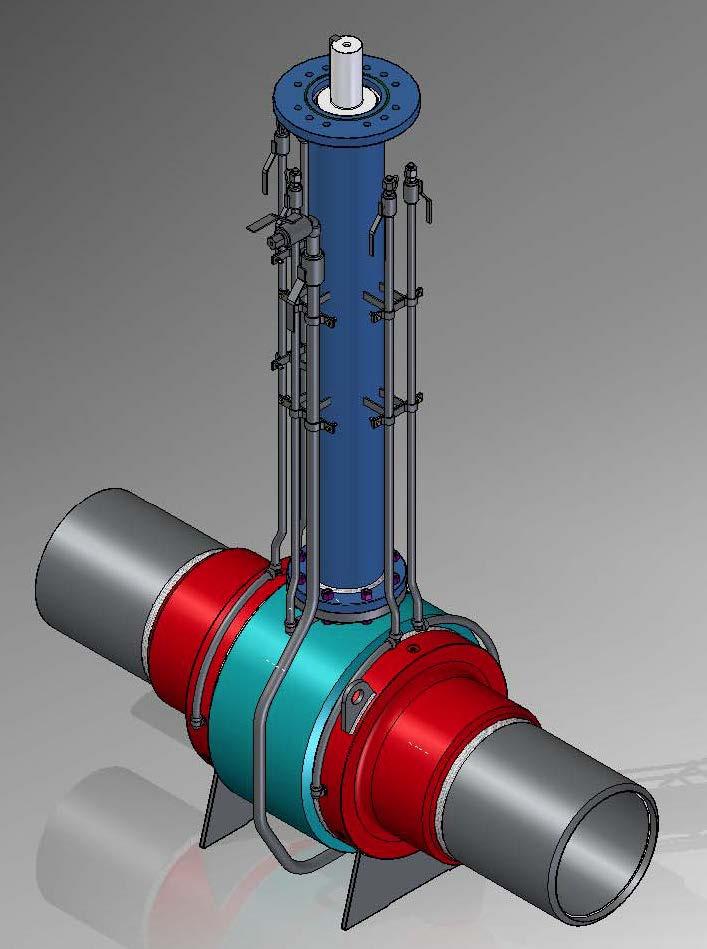

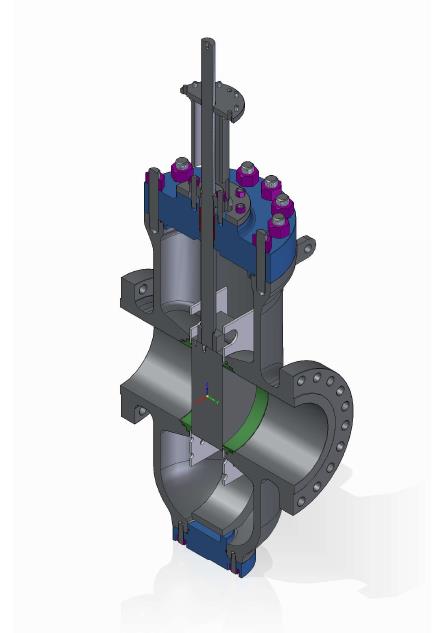

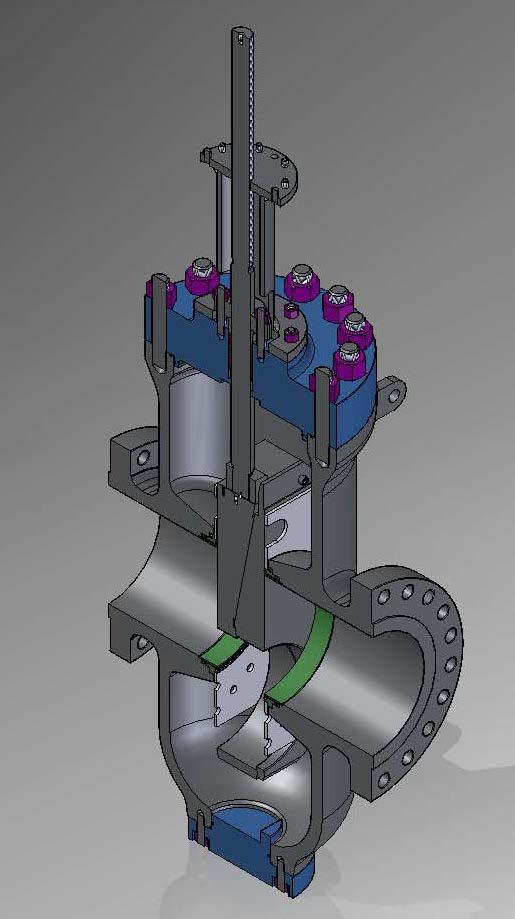

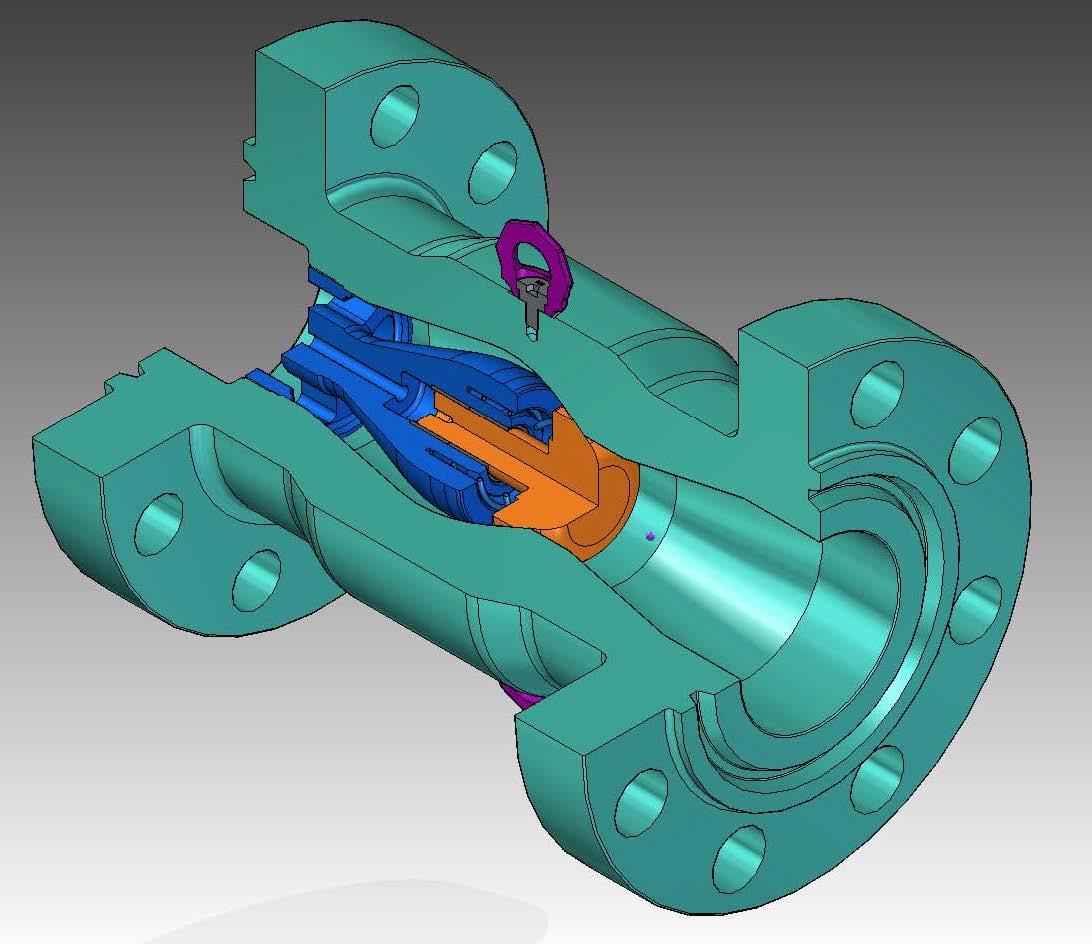

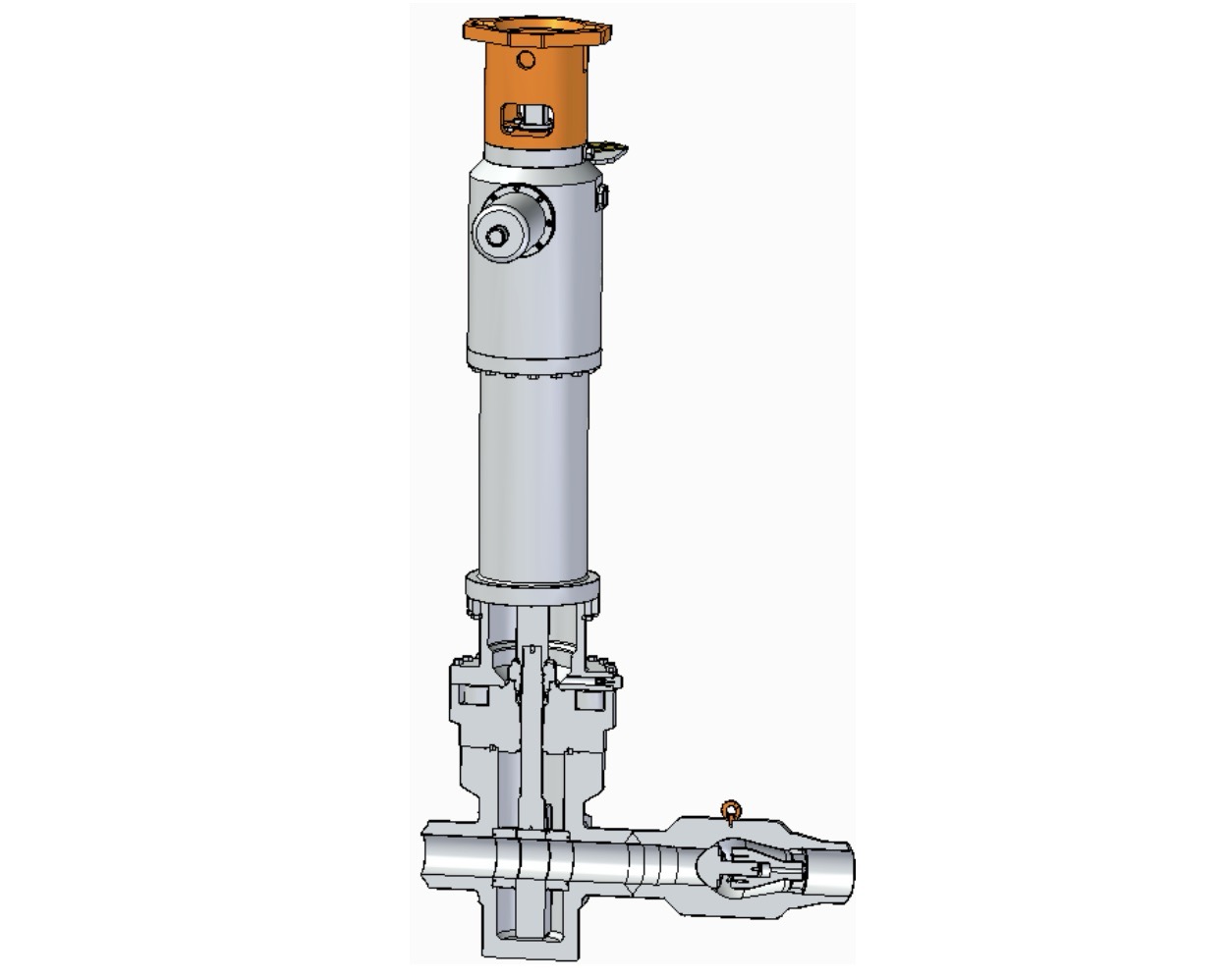

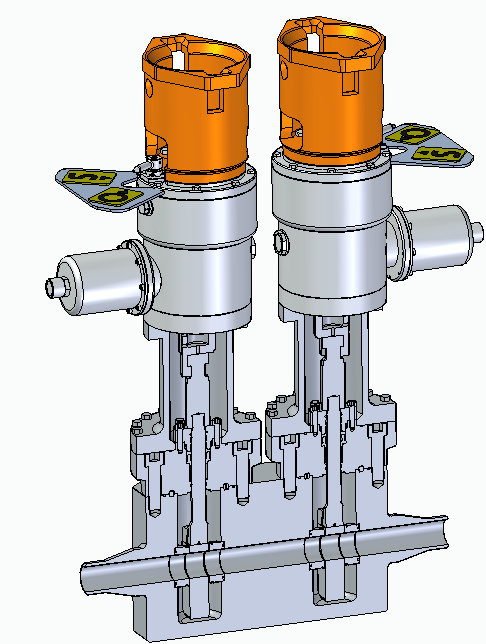

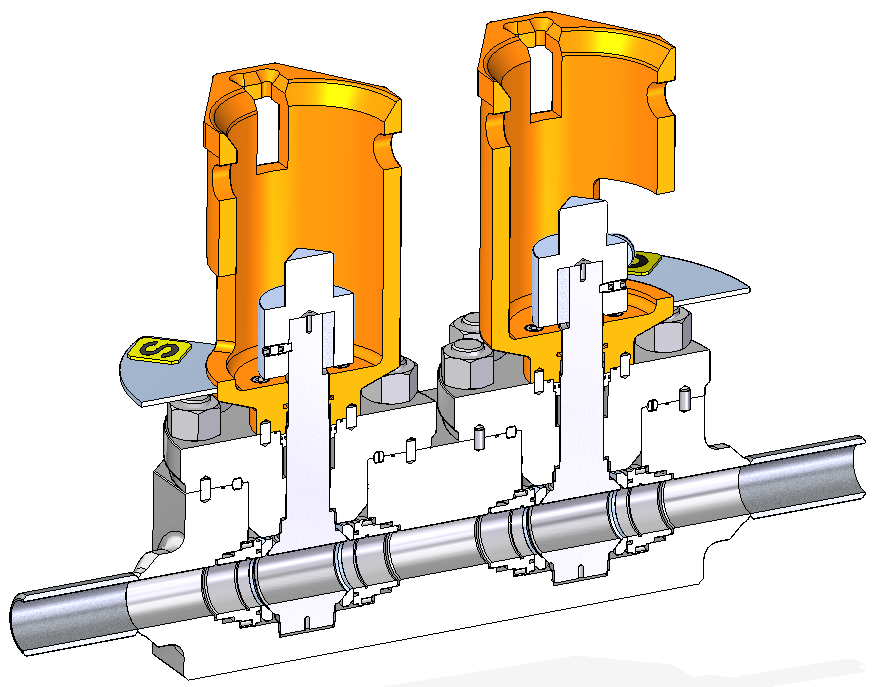

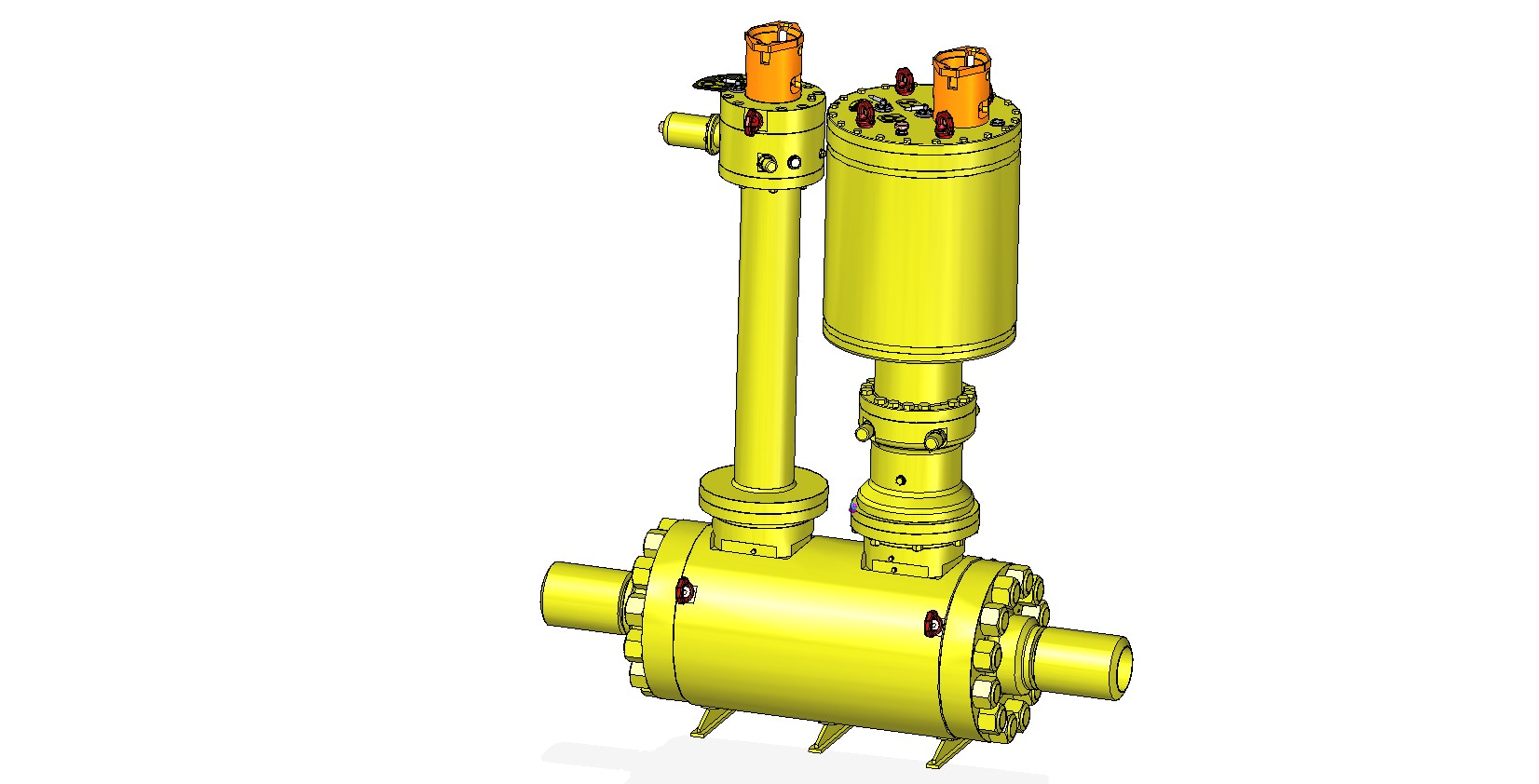

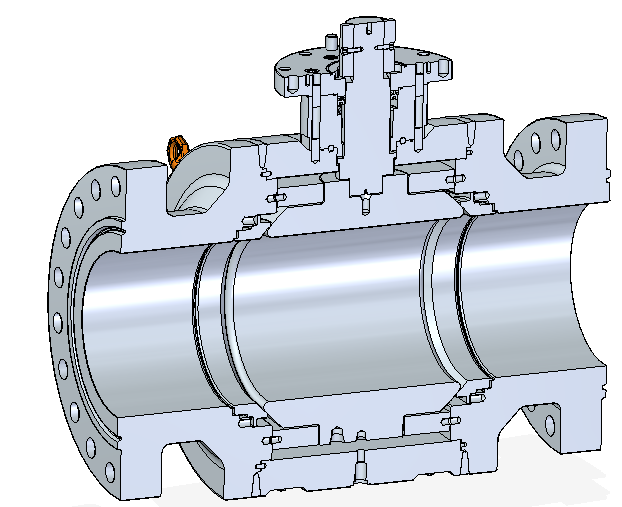

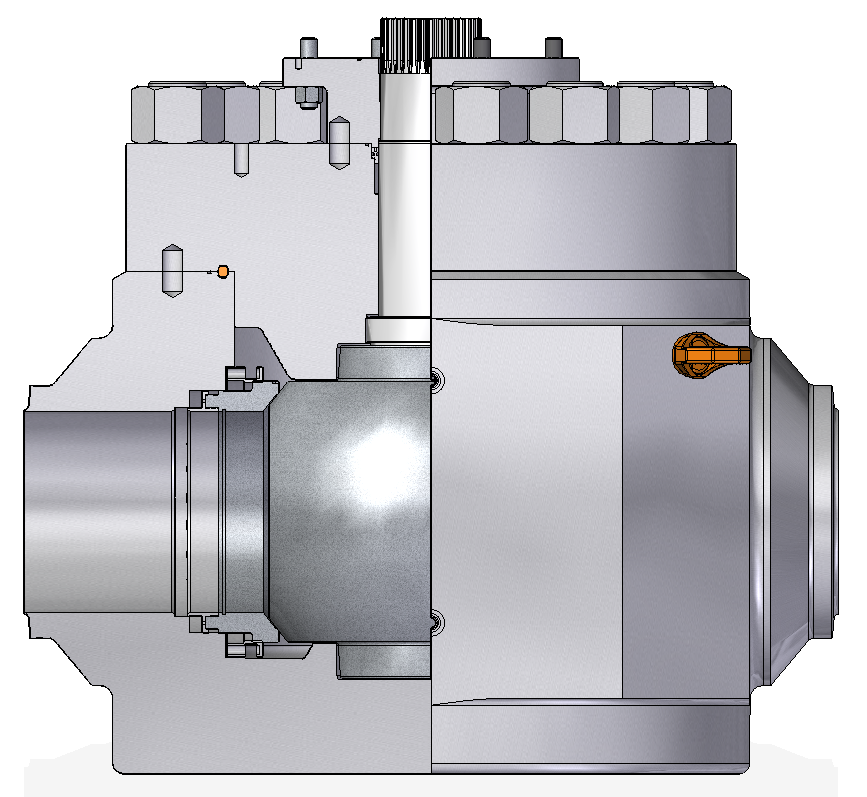

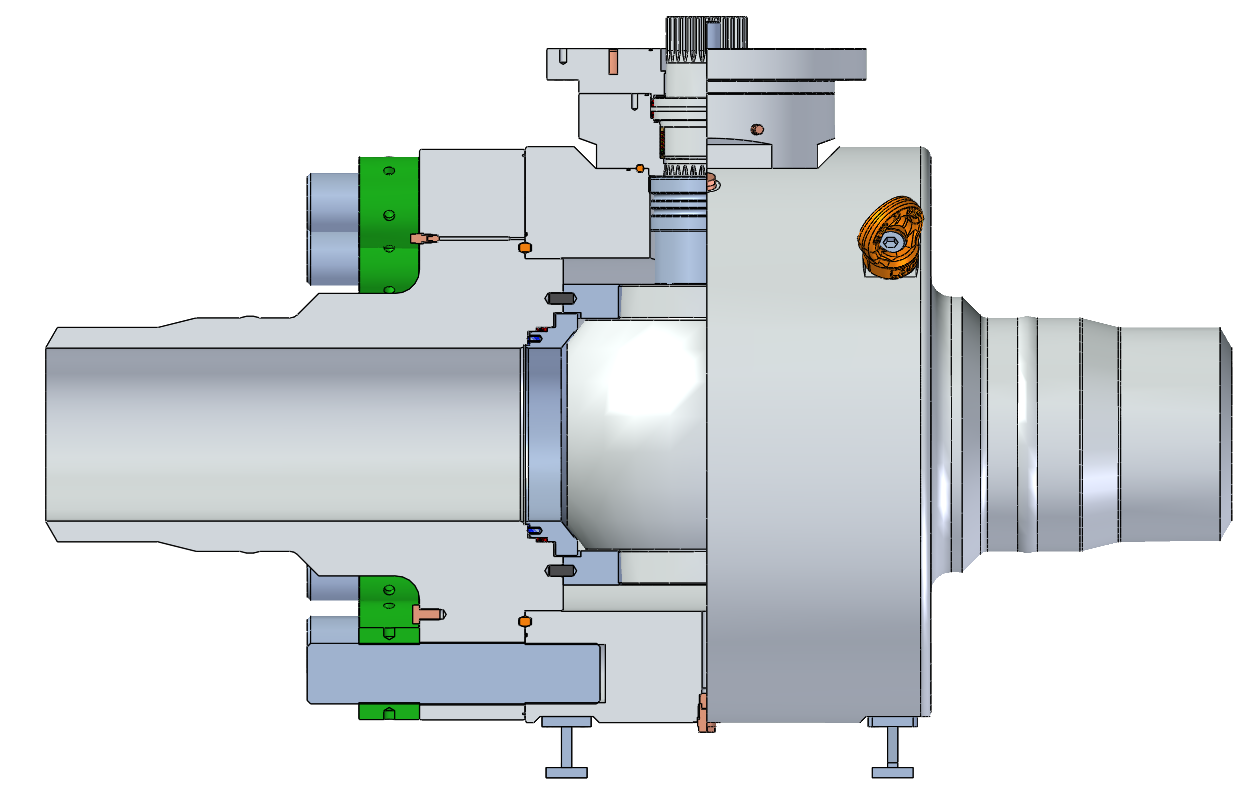

2/3 pieces side entry welded body design.

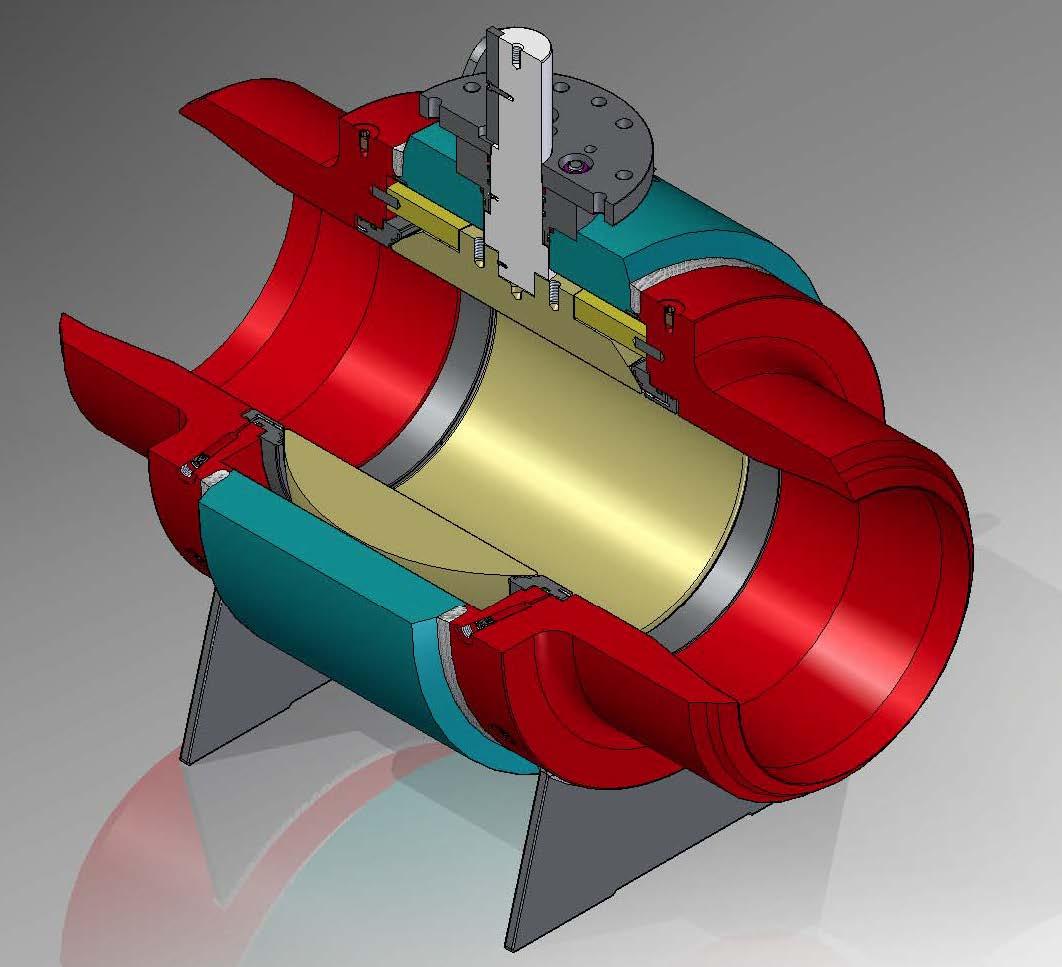

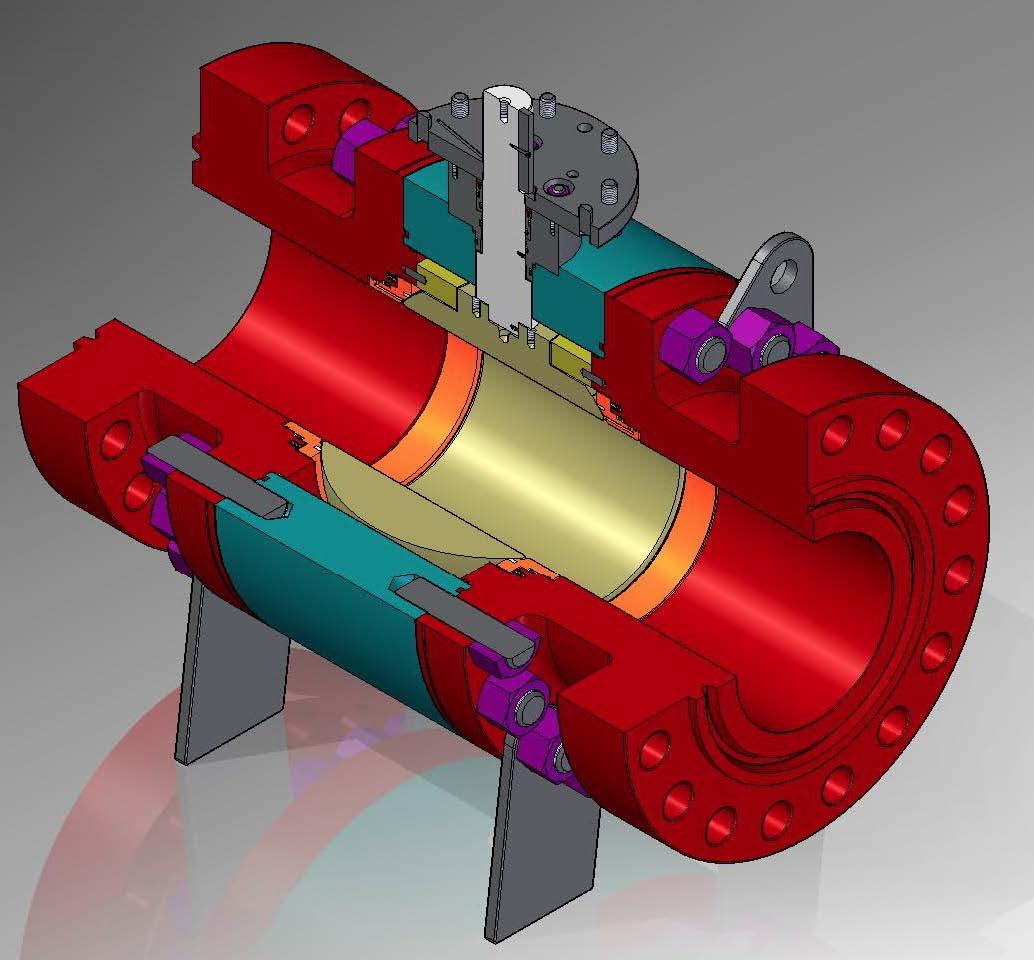

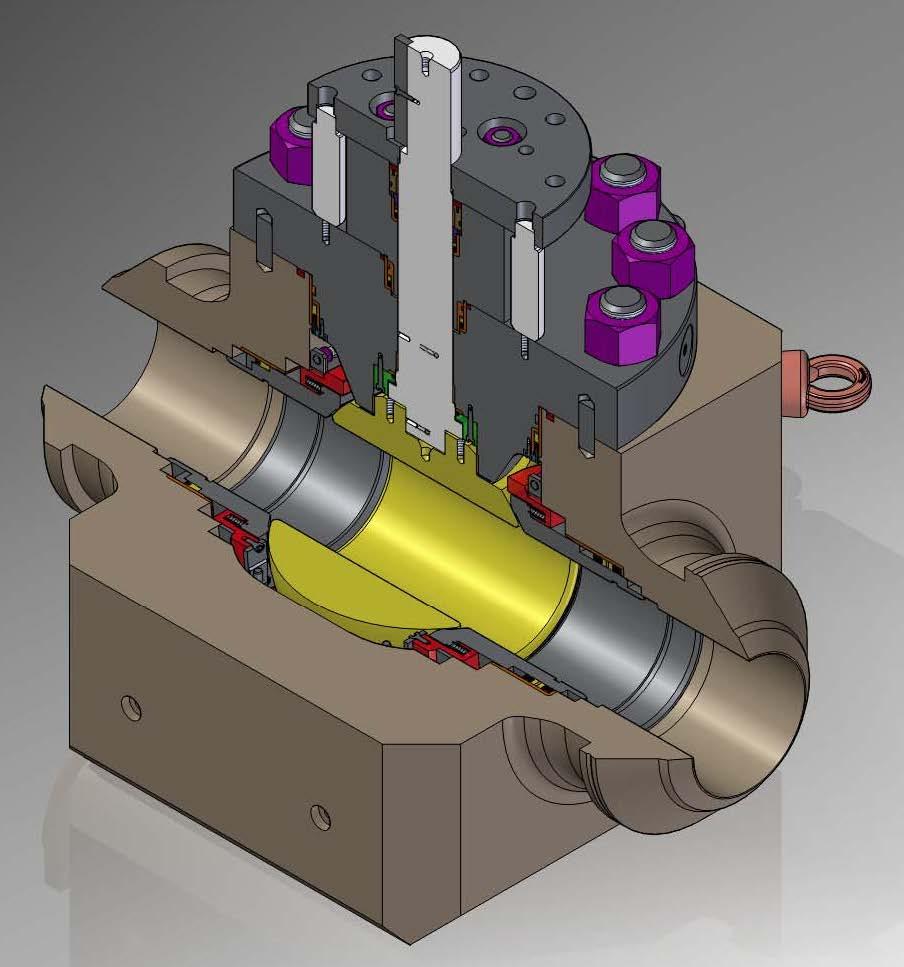

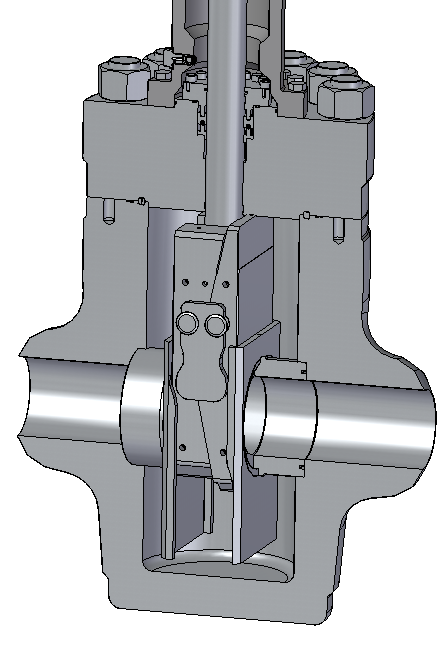

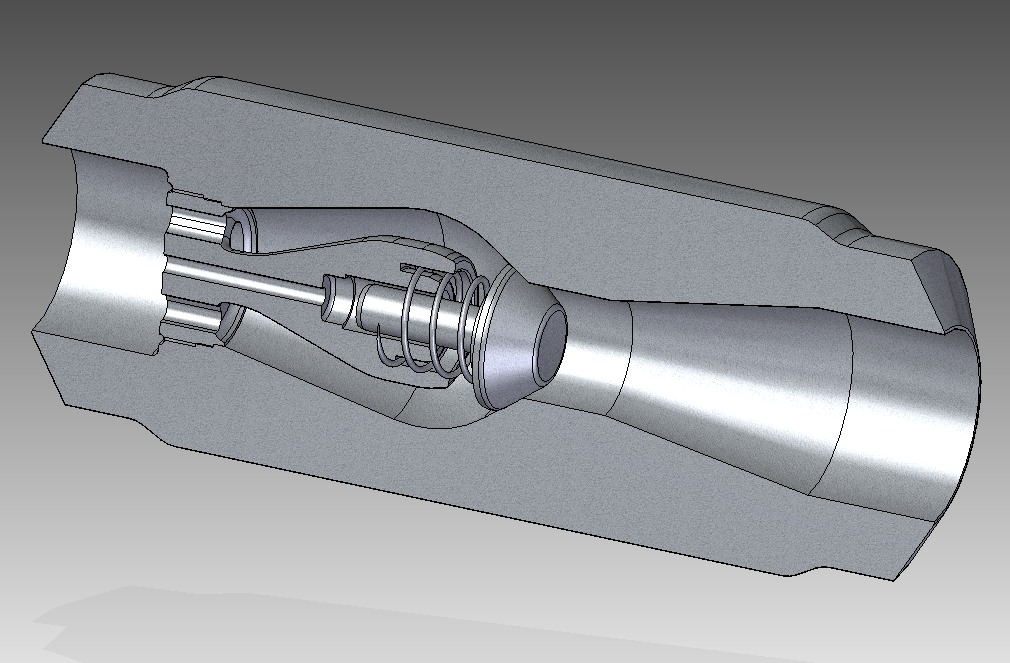

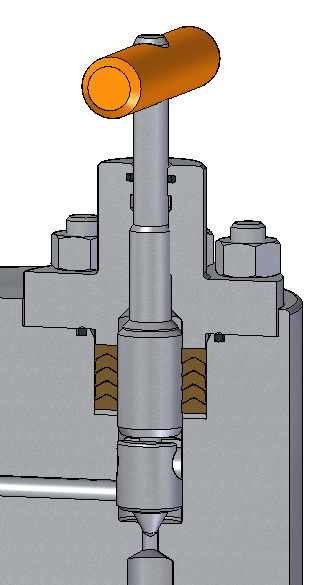

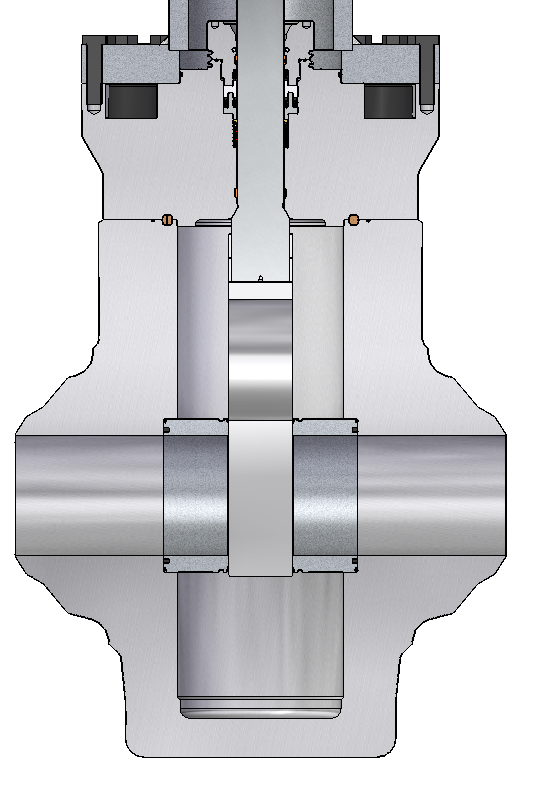

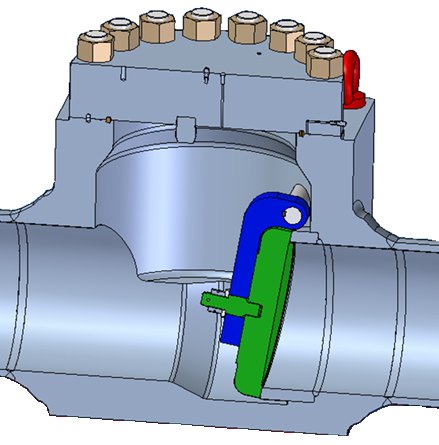

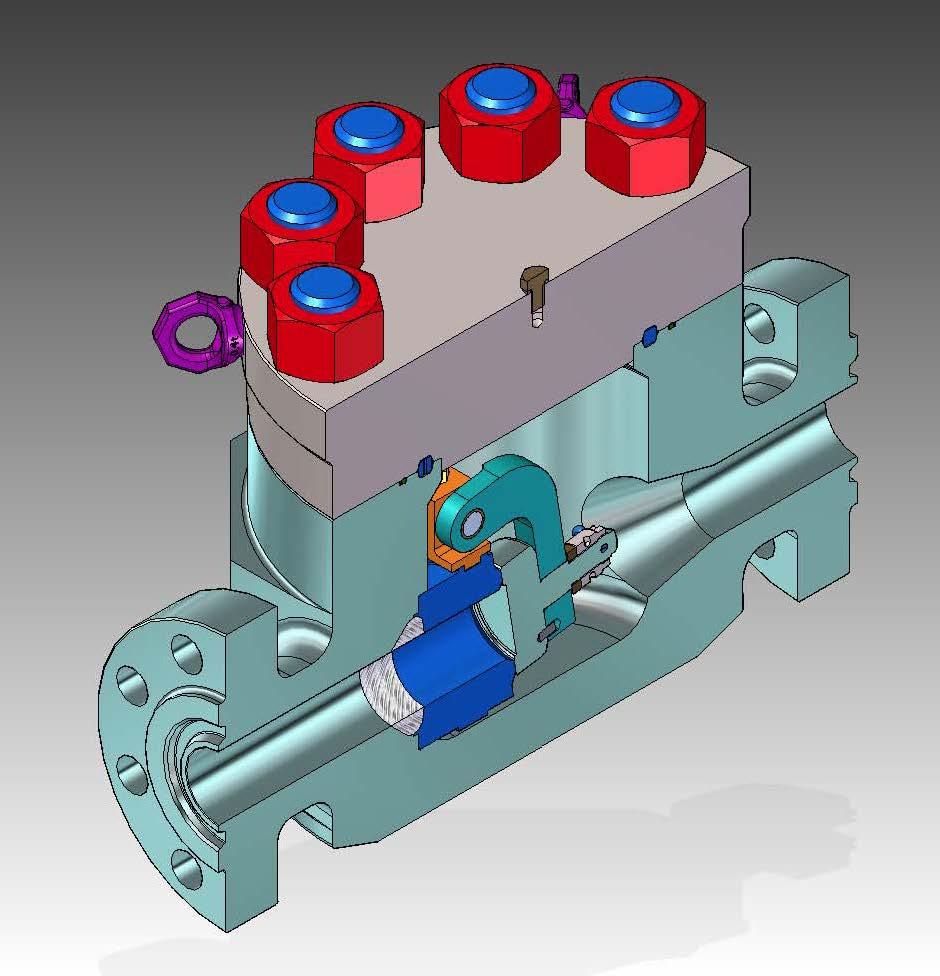

The ball of trunnion mounted configuration is supported by bearing plates hold by the end adaptors. In such a way the pressure loads are transferred to the valve body granting a smooth rotation of the ball with low torque levels and reduced seat seal wear.

On PERAR Trunnion Mounted Welded Body Ball Valves the potential leak paths are minimized making them suitable for buried installations and in general for gas transportation.

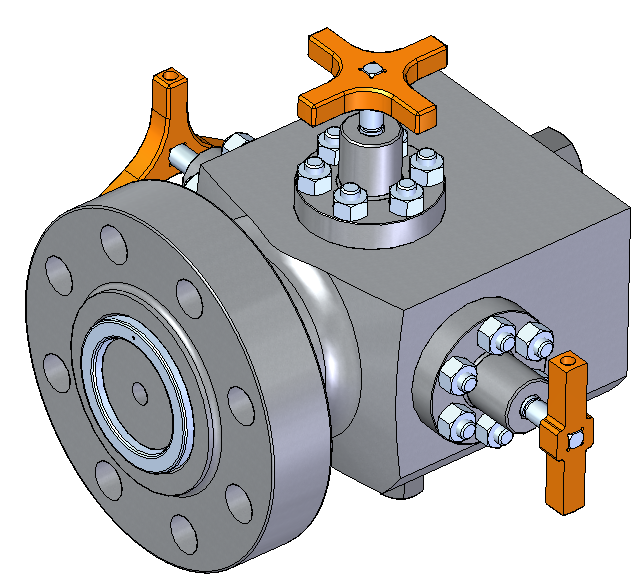

The weight and overall dimensions are optimized by applying a shaped design.

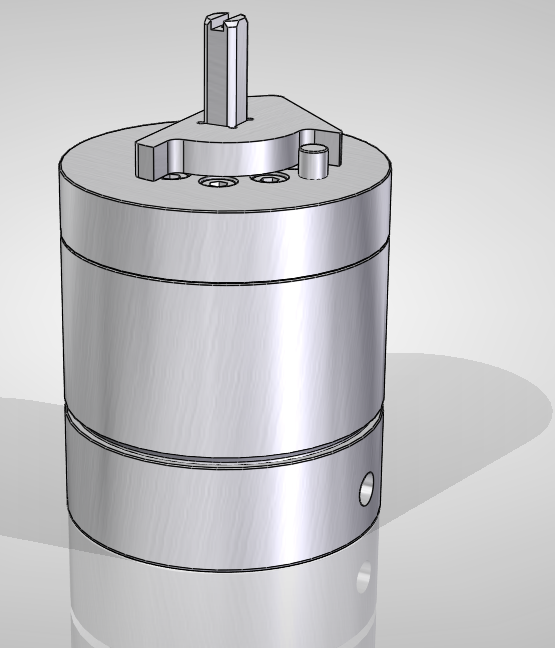

They are manufactured in a wide range of sizes and pressure classes from forgings.