Perar process

The ultimate aim of our valve production process is customer satisfaction. From conceptualization and manufacturing of valves to shipping and subsequent assistance, we dedicate maximum precision to every phase of the process.

Project start-up

PERAR’s projects begin by addressing client needs with tailored valves.

The Engineering Department assists, studies,

designs, and tests innovative products using various technical

solutions, all aimed at delivering superior results.

design

PERAR’s Technical Department uses a full CAD design and engineering system across all operations, from the initial quotation to the testing phase, plus a dedicated PC for Finite Element Analysis (F.E.A.) to optimize components.

Raw materials

For each job, we select the right material, such as carbon steel, stainless steel, duplex, super duplex, titanium, Incoloy, 6MO, Inconel, and special alloys. Thanks to our in-house process, honed over a decade of R&D, we guarantee the quickest time-to-market.

machining

At PERAR, quality is ensured by a global CAD-CAM System. Our machining and manufacturing area is divided into two lines: one for small sizes, primarily for floating and trunnion valves up to 16”, and another for medium to large sizes, handling valves up to 60”.

Assembly

PERAR’s key valve production process consists of three critical stages: Assembly (divided into lines for different sizes), Welding (involving multiple stations and mobile machines), and Testing. Specific functional tests at every stage of operation guarantee PERAR’s quality.

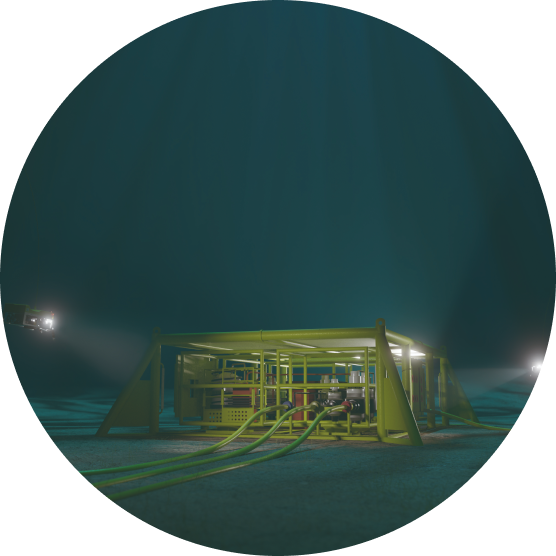

Testing

In a dedicated and segregated testing area, new modern

equipment is available to facilitate the smooth progress

of the most demanding orders, meeting any international

specifications through hydraulic-pneumatic tests covering

the full range of API 6D and API 6A sizes from 1/2” to 60”.

Perar testing facility includes the jumbo ultra-deepwater

hyperbaric chamber, which simulates external subsea

conditions at project installation depth down to 15,000

ft ~4,500 m water depth. All to ensure that Perar subsea

valves and actuators, manufactured from a single source,

will consistently perform as expected.

Finish and shipping

After completion of the testing phase and painting, PERAR valves are prepared for shipping with appropriate protection, documentation, and certification, and supplied globally. Our processes are optimized to minimize environmental impact and meet the latest market requirements.

after-sales

From bidding to after-sales, PERAR’s Customer Service team is constantly in touch with clients, ensuring continuous support throughout the valve’s lifespan. Each order is overseen by a dedicated product manager, providing real-time updates and proactive problem-solving to meet every need